What furniture plate do good?

[ Time:2014-03-05 Click:3190 ]

Panel of knowledge and plank of choice

The classification of the board

1, according to the material classification can be divided into: solid wood and man-made board two kinds big. Now in addition to will use solid wood floor and door leaf, the plates are usually we use manual processing of man-made board.

2, according to the forming classification can be divided into: solid wood, laminated, melamine board, joinery board, and so on.

The varieties of the board

1, solid wood

As the name implies, the solid board is the use of complete wood wood plank. The pattern plate durable, for nature, is the best of the selected in decorating. But as a result of such plate cost is high, and high construction technology requirements, used in the decoration but not much. Solid board generally classified according to plank material name, there is no uniform standard.

2, a multilayer

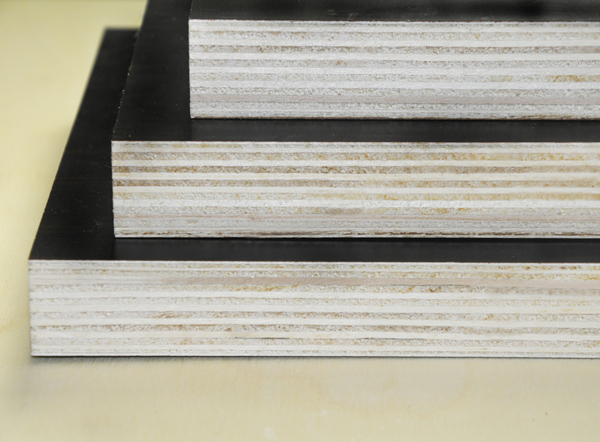

Sandwich plate, also known as plywood, inline commonly known as fine core board. By three layer or layers of a millimeter thick veneer or glue stick hot pressing plate. Is the most commonly used material is currently making furniture. A multilayer generally divided into 5 mm plate, organic board, 9, 12 mm plate, different thickness, such as 18 mile 16 mm plate and plate specification (1 mile to 1 mm).

3, joinery board

Joinery board, inline common weighs big core board. Big core board is composed of two splicing wood veneer glued the middle pressure. Big core board is cheaper than fine core board, the vertical (in the core material to distinguish) bending strength is poor, but the transverse flexural strength is higher.

4, particieboard

Particieboard is broken material with wood as the main raw material, then add glue, additive by the suppression of thin plate. According to the suppressing method can be divided into extrusion particieboard, flat crush particieboard category. This kind of plank main advantage is that the price is very cheap. Its shortcomings are obvious: poor strength. Make larger or powerful learning is generally not suitable for the demand of furniture.

5, density board,

Density board, also known as fiberboard. Is wood fiber or other plant fiber as raw materials, applying urea-formaldehyde resin or other applicable adhesive made from man-made plank, according to its density is different, divided into high density board, MDF, low density board. Density board because soft impact resistance, but also easy to rework. Abroad, density board is a good type of wood for making furniture, but because of the country on a high standard of board several times less than those of the international standard, so, the use of density board in our country there is a great room to improve quality.

6, melamine board

Melamine plate, full name is the melamine melamine-impregnated paper veneer man-made board. Is with different color or texture of paper soaked in the melamine resin adhesive, to a certain degree of curing and dry, the shop is in a multilayer, carpentry board, particle board, fiberboard, such as surface via hot pressing and decorative board.

The selection of board

Look at the environmental protection is not environmental protection

According to this year on January 1, the implementation of the "interior decoration decorates material to formaldehyde to release a set limit to" man-made board and its products, directly used in indoor building materials of formaldehyde release a quantity must be less than or equal to 1.5 mg per liter, if formaldehyde release a quantity to less than or equal to 5 milligrams per liter, must after finishing processing can be used in indoor, formaldehyde release a quantity to exceed 5 milligrams per liter is substandard. Take the unqualified wood home like giving new home a gas occurrence machine, buy building materials must look at the environmental protection not environmental protection.

1, joinery board the big core board:

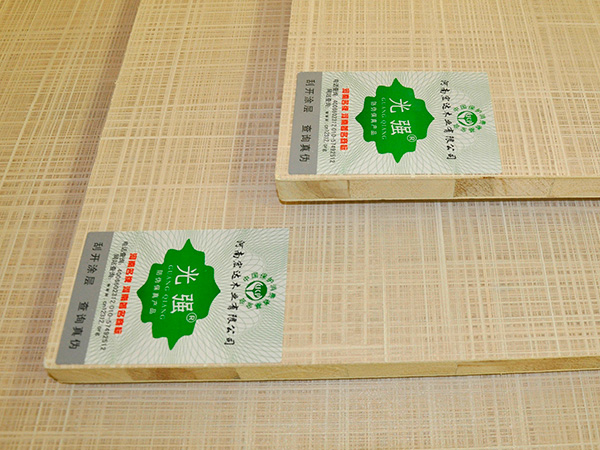

The middle of the joinery board with natural wood glue them into a core, two sides glued on very thin wood veneer, as the name implies big core board, is one of the main materials in decoration. Can do furniture and wooden door and door cover, central heating, curtain box of window, etc., the waterproof performance is better than that of particleboard and MDF. When choosing look at its internal timber, shoulds not be too fragile. Henan hongda wood industry co., LTD., the production of light intensity brand woodworking ecological board USES the straight cover technology, coating process, save time and effort can be avoided, reliable product quality, green environmental protection. Many consumers choose big core board, a look at the weight, look at the price. In fact, the heavier the big core board, its quality is bad. Because of the weight, the greater the more suggests that the board USES the miscellaneous wood. This made big core board, miscellaneous wood not nail the nail, to not be able to use.

In addition, the big core board price is very low, the quality would be very poor. Not gap is big, is to use the unqualified wood. So when the choice, you'd better choose a big core board of 130 yuan or so. The price of the big core board, its quality is stable. Market price in the RMB 55-85 big core board, cannot use at all.

Choose a big core board is appearance: look at edge of gap size, gap bigger inner core big core board agglutination intensity must not strong, the big core board surface must be dry, light net.

In addition, when you choose big core board, must be sawed a corner, check the quality. Joining together the small wood, inside the gap cannot be more than 5 mm, can't use a wood bark, wormhole and fast knot. Quality good big core board, between the small wood, agglutination gap closer.

2, medium density board than particieboard nail holding power is poor

Particle board is natural lumber after crushed into granule, the compressed into boards. Density board is to use powdered wood after pressing molding, flatness is better, but the wave resistance is poor.

Density board, by contrast, holding nail force is relatively particieboard is poor, if before and after the screw tighten loose, due to the strength of the density board is not high, it's hard to fixed, therefore rarely used for cabinet put oneself in another's position.

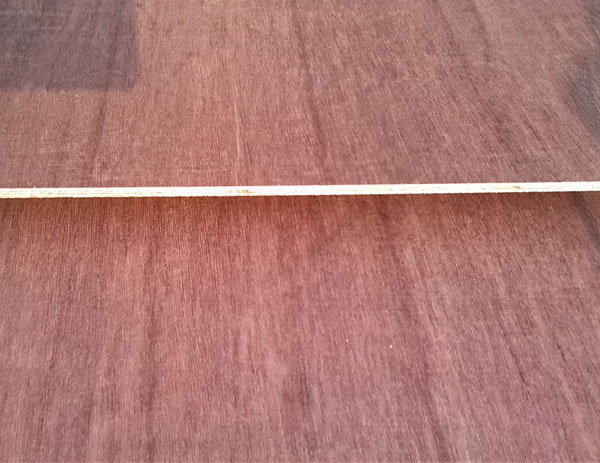

4, facing three-ply convenient and cheap

Sandwich plate, also called three plywood and three-ply board, layer number of different name. Mainly used in domestic outfit now facing three-ply, namely in the factory has already very thin solid wood veneer on plywood. Veneer plywood easy to use, the price also cheaper than oneself buy panels let construction group post come.

5, melamine double strap, not afraid of water

Shiny on the both sides of the plate is very hard, not afraid of water and fire, mainly used in furniture and cabinets.

6, veneer, manufacturing and the same effect as wood

Act the role of panel is made of high-grade timber wood grain obvious rotary cutting wood, very thin, only 0.3 mm the thinnest, but 2-3 mm thick. Common wood veneer color from shallow to deep, cherry, white ju, maple, red ju, northeast China ash, white oak, red oak, teak, rosewood, walnut, Bai Ying wood, dozens of varieties, such as wood of red shadow price does not poor.

Large area is used, it is better to buy directly facing three splint. If to achieve special effect, use veneer on local used alone, requires high technology.

Buy moisture content up to standard, the treated wood

When the lumber moisture content is higher than the environment balance moisture content (11.4% annual average moisture content in Beijing area), wood drying shrinkage, vice of hygroscopic and expansion of will. Wood is the main reason of the cracking and deformation moisture content is too high or too low. Qualified wood need after high temperature steaming and drying process, finally achieve the moisture content of the local level. As a result, the moisture content of timber is particularly important.

The expert reminds: don't pursue cheap

Experts tell us: don't pursue cheap, very cheap sale material is usually manufactured and the material of formaldehyde exceeds bid badly. Best to normal market, the sources of here is guaranteed. Buy a brand of materials. Because the wood is a family to decorate advocate material, in the purchase quantity is more, be careful when buy, had better with experienced people or shopping professionals. Decorating a company to buy, also can entrust a supply unit is they have a stable quality, the price may be lower, second, once appear quality problem, clear responsibility, a good solution.

The classification of the board

1, according to the material classification can be divided into: solid wood and man-made board two kinds big. Now in addition to will use solid wood floor and door leaf, the plates are usually we use manual processing of man-made board.

2, according to the forming classification can be divided into: solid wood, laminated, melamine board, joinery board, and so on.

The varieties of the board

1, solid wood

As the name implies, the solid board is the use of complete wood wood plank. The pattern plate durable, for nature, is the best of the selected in decorating. But as a result of such plate cost is high, and high construction technology requirements, used in the decoration but not much. Solid board generally classified according to plank material name, there is no uniform standard.

2, a multilayer

Sandwich plate, also known as plywood, inline commonly known as fine core board. By three layer or layers of a millimeter thick veneer or glue stick hot pressing plate. Is the most commonly used material is currently making furniture. A multilayer generally divided into 5 mm plate, organic board, 9, 12 mm plate, different thickness, such as 18 mile 16 mm plate and plate specification (1 mile to 1 mm).

3, joinery board

Joinery board, inline common weighs big core board. Big core board is composed of two splicing wood veneer glued the middle pressure. Big core board is cheaper than fine core board, the vertical (in the core material to distinguish) bending strength is poor, but the transverse flexural strength is higher.

4, particieboard

Particieboard is broken material with wood as the main raw material, then add glue, additive by the suppression of thin plate. According to the suppressing method can be divided into extrusion particieboard, flat crush particieboard category. This kind of plank main advantage is that the price is very cheap. Its shortcomings are obvious: poor strength. Make larger or powerful learning is generally not suitable for the demand of furniture.

5, density board,

Density board, also known as fiberboard. Is wood fiber or other plant fiber as raw materials, applying urea-formaldehyde resin or other applicable adhesive made from man-made plank, according to its density is different, divided into high density board, MDF, low density board. Density board because soft impact resistance, but also easy to rework. Abroad, density board is a good type of wood for making furniture, but because of the country on a high standard of board several times less than those of the international standard, so, the use of density board in our country there is a great room to improve quality.

6, melamine board

Melamine plate, full name is the melamine melamine-impregnated paper veneer man-made board. Is with different color or texture of paper soaked in the melamine resin adhesive, to a certain degree of curing and dry, the shop is in a multilayer, carpentry board, particle board, fiberboard, such as surface via hot pressing and decorative board.

The selection of board

Look at the environmental protection is not environmental protection

According to this year on January 1, the implementation of the "interior decoration decorates material to formaldehyde to release a set limit to" man-made board and its products, directly used in indoor building materials of formaldehyde release a quantity must be less than or equal to 1.5 mg per liter, if formaldehyde release a quantity to less than or equal to 5 milligrams per liter, must after finishing processing can be used in indoor, formaldehyde release a quantity to exceed 5 milligrams per liter is substandard. Take the unqualified wood home like giving new home a gas occurrence machine, buy building materials must look at the environmental protection not environmental protection.

1, joinery board the big core board:

The middle of the joinery board with natural wood glue them into a core, two sides glued on very thin wood veneer, as the name implies big core board, is one of the main materials in decoration. Can do furniture and wooden door and door cover, central heating, curtain box of window, etc., the waterproof performance is better than that of particleboard and MDF. When choosing look at its internal timber, shoulds not be too fragile. Henan hongda wood industry co., LTD., the production of light intensity brand woodworking ecological board USES the straight cover technology, coating process, save time and effort can be avoided, reliable product quality, green environmental protection. Many consumers choose big core board, a look at the weight, look at the price. In fact, the heavier the big core board, its quality is bad. Because of the weight, the greater the more suggests that the board USES the miscellaneous wood. This made big core board, miscellaneous wood not nail the nail, to not be able to use.

In addition, the big core board price is very low, the quality would be very poor. Not gap is big, is to use the unqualified wood. So when the choice, you'd better choose a big core board of 130 yuan or so. The price of the big core board, its quality is stable. Market price in the RMB 55-85 big core board, cannot use at all.

Choose a big core board is appearance: look at edge of gap size, gap bigger inner core big core board agglutination intensity must not strong, the big core board surface must be dry, light net.

In addition, when you choose big core board, must be sawed a corner, check the quality. Joining together the small wood, inside the gap cannot be more than 5 mm, can't use a wood bark, wormhole and fast knot. Quality good big core board, between the small wood, agglutination gap closer.

2, medium density board than particieboard nail holding power is poor

Particle board is natural lumber after crushed into granule, the compressed into boards. Density board is to use powdered wood after pressing molding, flatness is better, but the wave resistance is poor.

Density board, by contrast, holding nail force is relatively particieboard is poor, if before and after the screw tighten loose, due to the strength of the density board is not high, it's hard to fixed, therefore rarely used for cabinet put oneself in another's position.

4, facing three-ply convenient and cheap

Sandwich plate, also called three plywood and three-ply board, layer number of different name. Mainly used in domestic outfit now facing three-ply, namely in the factory has already very thin solid wood veneer on plywood. Veneer plywood easy to use, the price also cheaper than oneself buy panels let construction group post come.

5, melamine double strap, not afraid of water

Shiny on the both sides of the plate is very hard, not afraid of water and fire, mainly used in furniture and cabinets.

6, veneer, manufacturing and the same effect as wood

Act the role of panel is made of high-grade timber wood grain obvious rotary cutting wood, very thin, only 0.3 mm the thinnest, but 2-3 mm thick. Common wood veneer color from shallow to deep, cherry, white ju, maple, red ju, northeast China ash, white oak, red oak, teak, rosewood, walnut, Bai Ying wood, dozens of varieties, such as wood of red shadow price does not poor.

Large area is used, it is better to buy directly facing three splint. If to achieve special effect, use veneer on local used alone, requires high technology.

Buy moisture content up to standard, the treated wood

When the lumber moisture content is higher than the environment balance moisture content (11.4% annual average moisture content in Beijing area), wood drying shrinkage, vice of hygroscopic and expansion of will. Wood is the main reason of the cracking and deformation moisture content is too high or too low. Qualified wood need after high temperature steaming and drying process, finally achieve the moisture content of the local level. As a result, the moisture content of timber is particularly important.

The expert reminds: don't pursue cheap

Experts tell us: don't pursue cheap, very cheap sale material is usually manufactured and the material of formaldehyde exceeds bid badly. Best to normal market, the sources of here is guaranteed. Buy a brand of materials. Because the wood is a family to decorate advocate material, in the purchase quantity is more, be careful when buy, had better with experienced people or shopping professionals. Decorating a company to buy, also can entrust a supply unit is they have a stable quality, the price may be lower, second, once appear quality problem, clear responsibility, a good solution.

Previous :A whole wardrobe production process of the components and main process

Next:Wenqi ecological board and comparison of the advantages and disadvantages of joinery board